“Big Bang” or “Crawl, Walk, Run”

The numbers don’t lie – many studies have shown that greater than 90% of ALL companies that set out to implement Lean in a “program” approach (the approach most Lean consultants recommend and sell) fail to achieve anything like their original vision (something like the well-documented Toyota Production System). The recommended approach not only proves to be a waste of time and money, but often creates an aversion to continuous improvement.

So, what is the problem? The approach, not the goal. Looking at Lean from a distance, the program approach makes a key mistake. Consider someone who wants to get into high jumping. Where does a good coach set the bar when the athlete is just starting out – at 8 feet ¼ inch (the world record, set in 1993), or at 4 feet? No one would recommend starting at the world record height, for lots of reasons – the most significant being that it would simply cause the vast majority of would-be high jumpers to give up after a try or two.

Many Lean implementation plans seem to suggest that unless Lean is done like the star performers, it is not being done right. But like the world record holder for the high jump, Javier Sotomayor, who undoubtedly worked his way to the world record, starting at 4 feet, then 4-1/2 feet, 5 feet and so on, the star performers, the Toyotas of the world, also started out taking small steps at first and eventually got to where they are today, creating something that worked for them as they went, without expensive consultants, fancy slide decks or black belt certifications.

Top Down & Bottom Up

Let’s look at a sensible approach for small and medium sized manufacturing companies to get started with the cost saving, quality improving, customer focused approach to business operating systems that is Lean. The approach has been called “TOP DOWN BOTTOM UP”. What does that mean? Top Down is the expression of the rock solid unwavering commitment by the top executives of the company to always keep the vision front and center in everything the company does. It is the commitment of the CEO to talk about, to role model and to be the thought leader for Lean. Let me illustrate with a story from one of my recent clients, a startup in the modular house building industry.

Are Overhead Cranes Lean?

Let’s call the CEO “Sarah”. Sarah had learned about lean while working in a business supplying store fixtures for a global food service business operating restaurants. Needing to meet strict cost, quality and delivery targets, Sarah started to learn and experiment with the Lean approach to continuous improvement, and had success in getting others in the business excited about the potential as well. But Sarah was more interested in helping others through business and decided to start a modular housing company that would build attainable housing.

When I met Sarah at a meeting to lay out the basics of the business it was clear to me that she was enthusiastic about Lean. Through coaching she was able to construct a clear vision about how to run a Lean business, encompassing attitudes to customers, suppliers, employees and the community. This became the go-to vision to consult whenever a decision had to be made.

One such decision stands out for me. We were discussing how to move the modules through the factory. Traditionally, overhead cranes are used, and this was the initial thought here as well. But when I reminded Sarah of the vision and asked: “Are cranes Lean?”, we started a deep conversation about safety, flow, line-of-sight management, operator independence and other topics.

I remembered and told the story of an early consulting engagement at a steel mill where we reduced changeover time from four hours to less than one hour simply through careful management of cranes, and drew the conclusion that cranes should be avoided as much as possible in the production flow. I also thought back to methods of moving large stamping dies that I had experience with, and suggested that the factory consider what is called “air casters” (small devices that use compressed air to lift heavy items a few millimeters off the floor).

The discussion went on and eventually the building was built to require fewer cranes. The floor was constructed to be very flat so the air casters would work flawlessly. In itself, the floor may have a higher cost, and air casters are not inexpensive, but the solution allowed flow, safety, operator independence and good organization to be realized, all due to the insistence by Sarah of the priority of the vision. This is TOP DOWN.

The features of TOP DOWN are:

- Ensuring that the vision is clear for everyone – through training, conversations, slogans and posters and other means of communication, and role modeling.

- Supporting the actualization of the vision – through funding, decisions, focus and other ways of demonstrating bias for aligned actions.

So, TOP DOWN creates the culture and direction but does not make detailed decisions.

Let Those Who Do the Work Design Their Own Processes

BOTTOM UP means that all the details and small improvements, all the daily practices and standards, come from the people who are directly involved in the work – operators, supervisors, mechanics, material handlers and the rest. When a problem is identified, whether through daily tracking against requirements or through the Voice of the Customer, the supervisor will initiate the improvement process by having people observe the process in action and gather data. Through trial and error a consensus will emerge for how to change the process to meet requirements or satisfy customer expectations. Expert help may be needed for training or to coach the team. The tools used for analysis and change are not complex and rarely need special skills. I will illustrate the process from a client engagement. A transit vehicle cleaning organization was under pressure from their client to improve the cleanliness of the transit vehicles since the transit operator was getting poor grades for cleanliness from the ridership. I coached the cleaning supervisor. Let’s call her “Dolores”.

Dolores did not have a lot of knowledge of continuous improvement methods but was willing to try my suggestions as it meant keeping the contract that kept her crew of 20 employed. The improvement process started with a workshop where cleaners and supervisors described the processes they employed, and the problems they encountered. The processes were given a short descriptive name, and the problems were likewise named. At the end of the workshop each cleaner was given a small notebook and asked to record as many of the start times and finish times for each process, any associated problems and where they were at the time of each recorded process. After two weeks the team gathered again and talked about the experience.

Some had lots of data and others not so much, but it was all collected and analyzed for presentation back to the team. Then the team got to work looking at the data and identifying problem areas. Time standards for specific processes were agreed and suggestions made for how to meet them. Much depended on laying out the work to distribute the time more evenly.

Other improvements needed outside help, such as repairs to electrical outlets, improved crew transport from train consist to train consist and other small inexpensive improvements to working conditions. Coordination with other crews doing work, such as mechanics who often had dirty shoes, was also required. Once the new processes were implemented, I worked with Dolores to set up daily walks of the clean cars to find additional issues and help her communicate the necessary cleanliness standard to everyone. Through a daily audit process the new processes became habitual. The outcome was a major shift in customer comments to the transit authority over a two month period, from very negative to mostly positive. This is BOTTOM UP.

The features of BOTTOM UP are:

- Operator analysis and suggestions – through training and coaching without prejudice to the proposed solution, through assistance with coordination and escalation as required, through the use of simple tools not requiring expert knowledge.

- Responsibility for results by those directly involved in the work – through self-audits, visual management through simple white boards, acceptance of the needs of the business and work towards meeting them.

- Small team activities – through self-managed teams that use part of the working day to step by step work through an improvement plan.

Here we understand that BOTTOM UP takes the direction and works within the culture to make significant changes to the business.

Traditional vs Lean Thinking

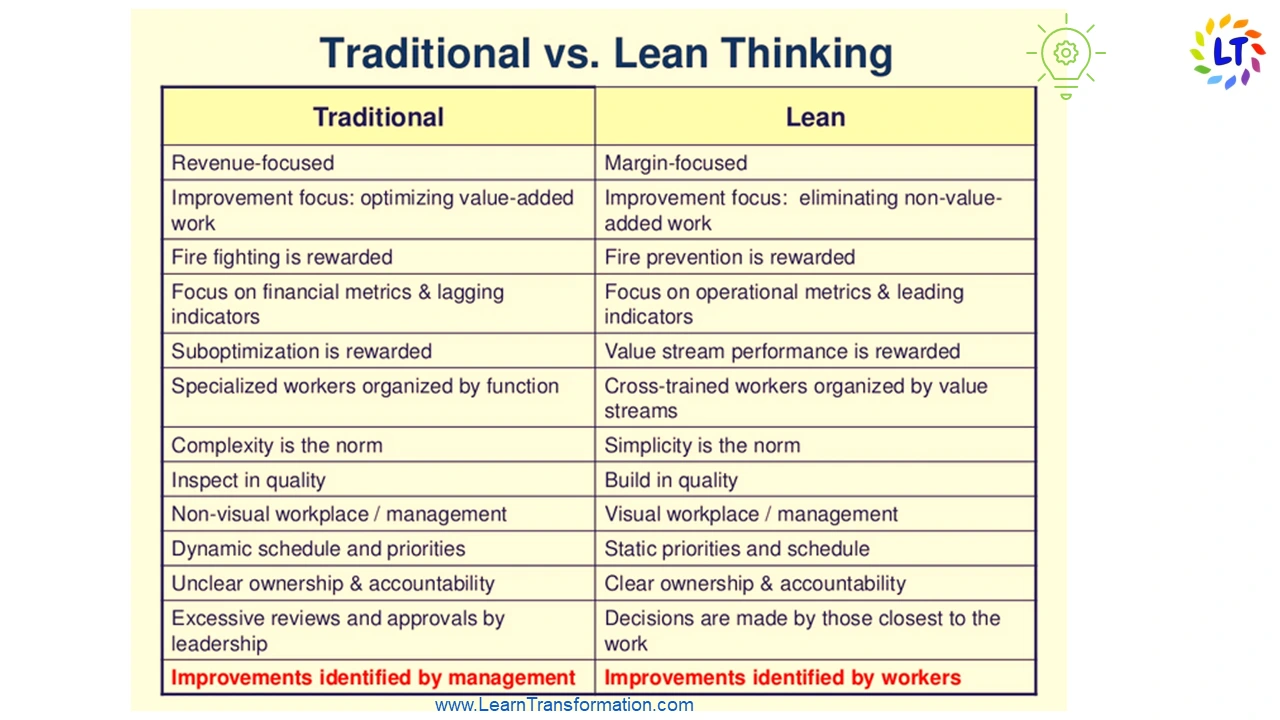

Many will ask what the role of technology, especially systems, is in a Lean enterprise. First of all, Lean enterprises employ the same kind of systems used by most other enterprises. Perhaps the key difference is that the systems employed are used in a more limited way, giving preference to operational over financial metrics and management, visual management and putting the customer relationship first. The systems used are therefore adjusted to reflect this, rather than used out of the box. Here is a handy chart from LeanTransformation, described as “A platform to learn and transform yourself into what the world is in need of today”, showing the difference between Lean thinking and Traditional thinking (as often taught in Schools of Management):

5W1H Analysis

Let’s try to put some of these ideas into another format, using a simple Lean tool for describing something clearly, called 5W1H (shorthand for what, where, when, why, who, how) which I wrote for another blog post recently.

There is a lot of discussion and disagreement about the meaning of “true” Lean. Perhaps it can be understood using one of the lean tools – 5W1H. Also, we can look historically to try to understand the inspiration for Lean.

Before it was called “Lean” it was referred to by a number of names – JIT, Japanese Manufacturing Techniques, Toyota Production System (or any number of other Production Systems, e.g. Canon Production System). The term “Lean” came from studies at MIT, mainly about the difference between how various automotive companies set up their production systems, supply chains, human resource policies, and so forth, to explain the competitive deficiencies of the American “Big Three” compared to companies based in Japan.

Some of the original inspirations were “Peace and Happiness Through Prosperity”, as stated by Matsushita (of Matsushita Electric, which became Panasonic), or “Survival” and stated by the Toyoda family. Womack and Jones in the book “The Machine That Changed The World” were looking for a way to lay out a program to become internationally competitive in the automotive industry, using Toyota as the primary example.

The 5W1H looks something like this:

WHY (purpose) – simultaneously reduce Cost, shorten Delivery Time (order to cash) and increase Quality (which I call the QDC triple optimization)

HOW (process and strategy) – Voice of the Customer + Just-In-Time + Respect for People/Community/Stakeholders = a new way of thinking

WHAT (tools) – the Lean Toolkit, Lean Leadership, “Toyota Way” thinking, Operational Excellence, Agile, TOC

WHEN (plan) – daily improvement (small steps, no cost), daily gemba walks (standards dialogue, kata), leader standard work, projects to create a significant leap in performance (including SixSigma)

WHERE (areas of effort) – all aspects of the business need to be involved and aligned and look for opportunities to achieve the purpose (operations, accounting, supply chain, human resources, IT, engineering, R&D, sales and the rest)

WHO (responsibilities/participants) – everyone has a role to play and a duty to work towards realizing the goal using the appropriate tools and ways of thinking (all hands on deck)

The more of this approach a client is able to adopt and live by, the more competitive they will be. But, most companies can only do so parts, and this is fine. Bit by bit is also Lean – this is not an all or nothing.

How to Start

So, how to start with Lean – let me repeat my belief that the “big bang” of “program” approach rarely if ever works well for small and medium enterprises. The approach I recommend is the Top Down Bottom Up approach: Top Down – Executive education, experimentation, visits to “model factories” (through some of the organizations arranging tours to Japan and elsewhere where there are factories well along the Lean path), attendance at Lean conferences and membership in local organizations such as a Lean Consortium. Bottom Up – Supervisor led experimentation with a few Lean tools, learning events such as week-long improvement workshops in a selected area, usage of a few visual management boards and team study of how production actually flows, where information comes from and how suppliers actually serve the production system.

From my experience, there are a few Lean tools that are easy to understand and have the potential to pay off immediately. They are also suitable for implementation in week-long workshops in a team area.

- Process Mapping (Value Stream Mapping or VSM) – this is a tool for building a picture of how a given product or group of products flow through the successive stages of the transformation from raw materials to finished goods. The map itself is created through a team process and may in itself not look very impressive. The discussion around why the production process is set up in the way it is and how well it is performing its intended goal can be very impressive. It challenges received wisdom and is therefore the beginning of a key Lean goal – the development of the ability to think critically about systems and change.

As for having a fast payoff, I have often found that once laid out as a map, it is clear to everyone that there are steps that no longer serve a purpose and can be immediately eliminated. Savings from thousands of dollars to hundreds and even amounts in excess of a million dollars have been found through this simple tool. Of course there is hard work in changing processes and many ideas brought to light during the mapping process will take a while to implement and challenge the creativity of the team. - Short Interval Control (SIC) – this is a tool for challenging the production system to operate as conceived. SIC is the process of checking progress against plan/standard and problem solving as the actual performance deviates from expectation to make small improvements to get back to plan. It is owned by the production supervisory team.

Typically SIC is implemented on a large white board. The daily, weekly and monthly production and shipping plan is laid out by product and once or twice per day or once per shift the actual production and shipping is compared to plan. Then remedies, escalations and causes are discussed along with suggestions to be tried during the next review period. This process continues, finding the issues and concerns and using suggestions from those working in the process to improve the process.

It can quickly turn a poor process into a star performer. I have worked with a client to go from chronic late shipping and loss to a profit and close to 100% on time performance. In this case, a potential loss of a large customer turned into a blossoming business relationship.

Final Words

There are many other similar tools and approaches which are easy to start and offer quick results. This is not to say that all Lean activities are simple and free. Sometimes, big leaps need to be made to stay at the forefront of your industry. Once you are under way, start considering the ways of locking in the improvements – visual management using the right performance indicators, published standards, audits and daily check-ins with the process (sometimes called “gemba walks”). All these tools show that what is happening on the shop floor matters.

Make sure to remember that any shortcomings are opportunities to learn and do better in the future, not reasons to punish. Learn about “eye for waste”, the process of seeing everything that takes place on the shop floor (and in the office – a lot of what we have talked about is relevant there too) through the lens of the key wastes (fluctuation, stress and overburden, overproduction, overprocessing, excess inventory, excess movement of materials, excess motion of people doing a job, waiting, defects and unsafe conditions). Show respect for people, the community and the environment by ensuring they are not treated as a means to an end but as essential partners of the business. Lead with humility (servant leadership) and a clear vision. And finally let me (somewhat selfishly) suggest that a coach can be invaluable in keeping everyone honest and focused and brings both experience and expertise that takes years to develop to help answer the many questions that come up on the journey.

Ready to revolutionize your manufacturing process with Lean principles?

Connect with Anders today and unlock the full potential of your operations. The proven strategies, gleaned from real-world experiences detailed in these articles, will empower your organization to minimize waste, optimize processes, and maximize productivity. Don’t let outdated practices hold you back – take the leap towards operational excellence with Anders Nielsen by your side.

On Cansulta, we believe no business leader should have to face any challenge alone. Our online platform lets you find and collaborate with pre-vetted, expert consultants at a fraction of the cost of traditional firms.